As a digital color printing device, the price of UV flatbed printer is not low. If the UV flatbed printer is operated correctly, it can prolong the machine life and improve the printing quality. Here are some matters that need attention:

I. Before operation

(1) First check the size, thickness and type of the printing material, and then decide how to pass UV.

(2) Before operation, check whether there are any debris on each part of the machine. Only after confirming that there is no debris can the machine be turned on to avoid replacing the debris into the machine and causing damage to the machine.

II. Turn on and off the machine

(1) When turning on the lights, turn on the lights in sequence, with an interval of about 1 minute between each light, and do not turn them on at the same time.

(2) After turning off the lights, the fan should continue to run for a while until the lamp tube cools down.

(3) If you want to start the second time after turning off the lights, you must wait until the lamp tube is completely cooled before starting it, otherwise it will not start when the surface temperature of the lamp tube is very high.

(4) After turning on the light, the production cannot be started immediately. There must be a period of lamp preheating time. When the temperature is high in summer, the preheating time is short; when the temperature is low in winter, the preheating time is longer, about 2-3 minutes. If the UV machine has a strong and weak light device, the light should be turned on in the strong light mode to shorten the lamp preheating time. If weak light is required during production, it can be adjusted to the weak light mode after the preheating is completed.

III. Lamp maintenance

(1) The maximum service life of the UV lamp is generally 800-1200 hours, and it should be replaced when the service life is reached.

(2) During the use of the UV lamp, use anhydrous ethanol and gauze to clean the surface of the lamp tube and the reflector on the surface of the reflector cover at an appropriate time (1-2 months), and then rotate the UV lamp tube 180°. The reflector cover should be replaced after the mirror effect is lost.

4. Speed adjustment

(1) Method for selecting the best speed: First, pass the product through the UV curing device at a certain speed. If it is cured, speed up again until the product passing through the curing device just cannot be completely cured. The speed at this time multiplied by 0.8 is the best speed.

(2) In addition, attention should be paid to the use time of the UV lamp. As the use time of the UV lamp increases, the energy will decay and the speed should be slowed down accordingly.

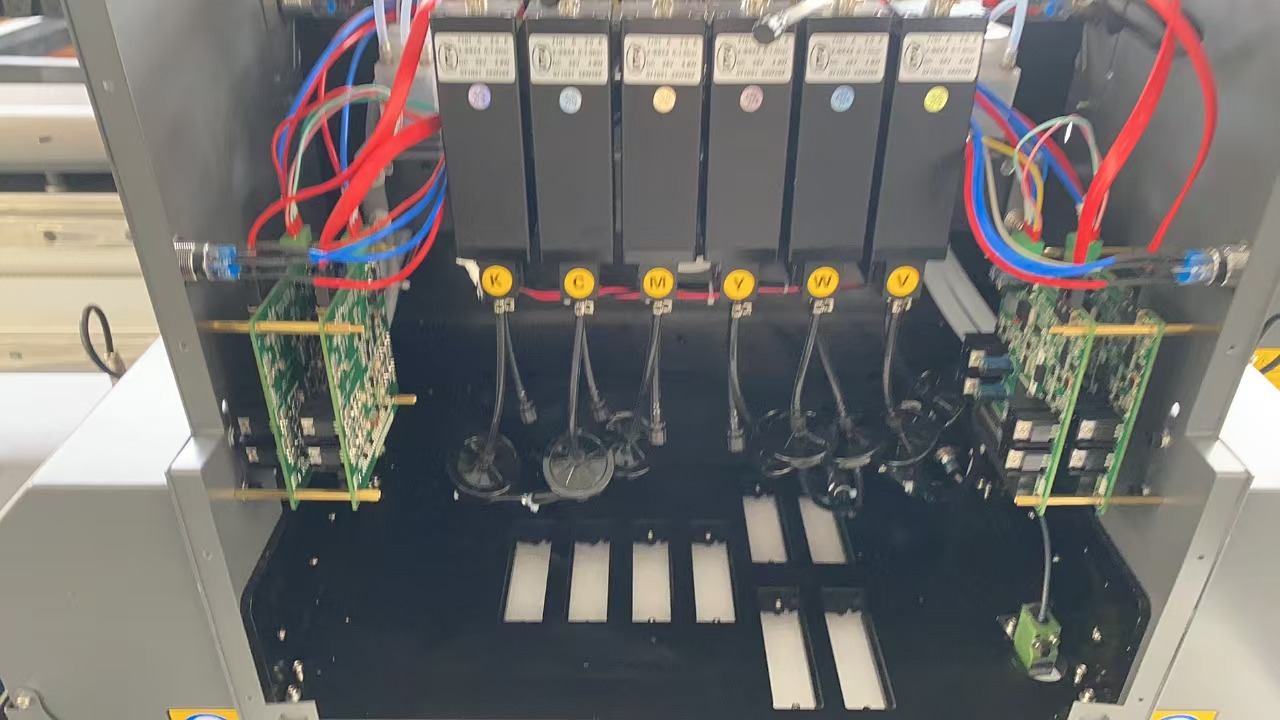

5. Transformer and capacitor

(1) The transformer input line should select the appropriate terminal according to the voltage on site.

(2) After use, the capacitor must be discharged if it is repaired to avoid capacitor discharge and injury.

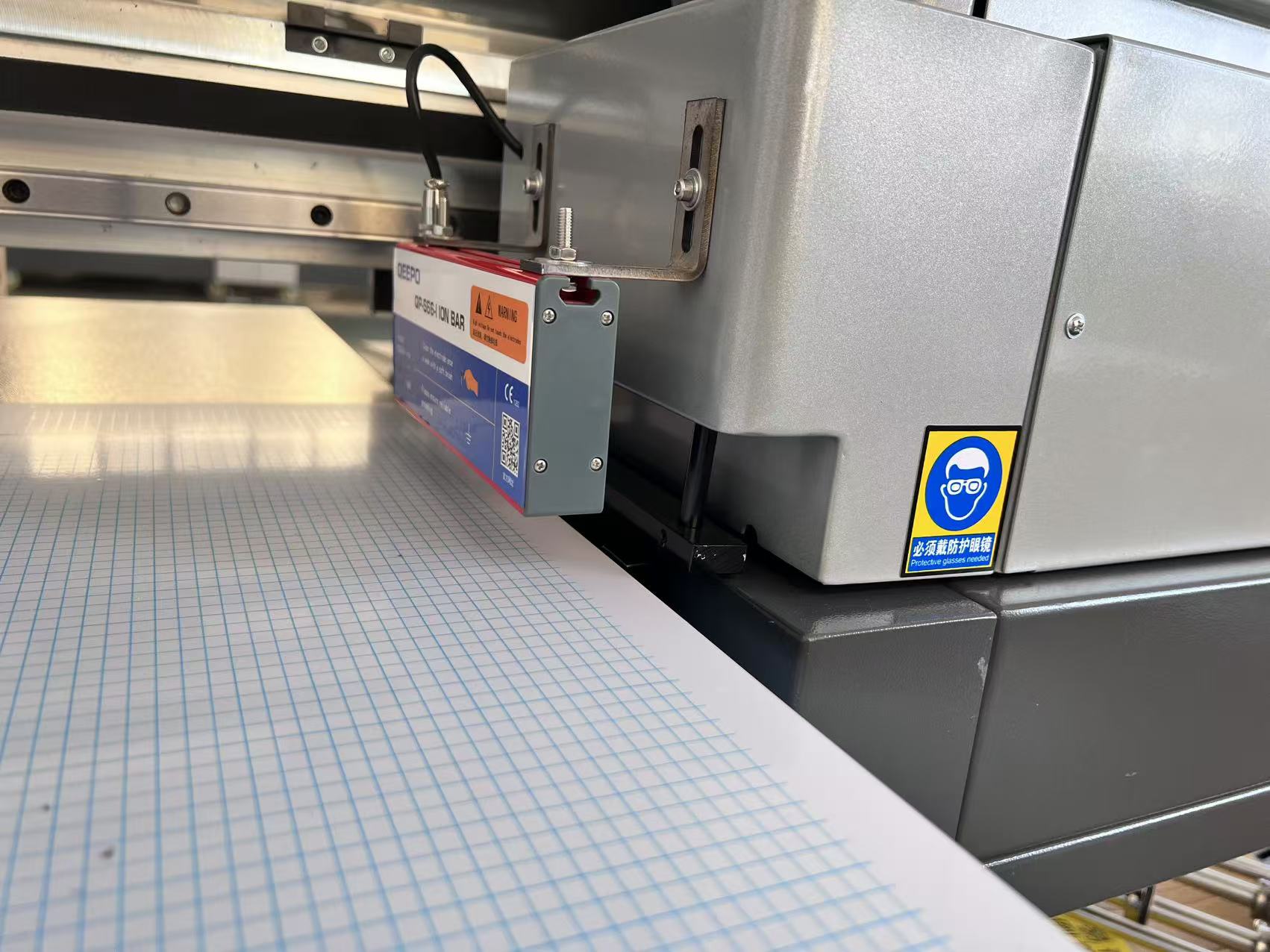

6. Ultraviolet rays can damage the eyes and skin. Please do not look directly at the surface of the lamp when turning on the light, and do not let ultraviolet rays irradiate the skin.

7.When adding ink, try to avoid contact between ink and skin. UV ink is corrosive to leather cream. If contact is required, wear labor protection products such as rubber gloves for protection. In case of contact with skin, wash it immediately with plenty of clean water, otherwise it will cause skin rot.

The Versatility of UV Flatbed Printers

In the field of modern printing technology, **UV flatbed printer stands out as a revolutionary tool that changes the way businesses print. Unlike traditional printers, UV flatbed printers utilize ultraviolet light to cure or dry the ink as it prints, allowing for immediate processing and reducing the risk of smudges. This unique feature makes it ideal for a wide range of applications, from signage to promotional materials.

One of the most significant advantages of the UV Flatbed Printer is its ability to print on a variety of substrates. Whether it’s wood, glass, metal or plastic, these printers can handle it all, making them versatile. This capability opens up new avenues of creativity, allowing designers and businesses to explore unconventional materials and create unique products that stand out in a crowded marketplace.

Additionally, the quality of prints produced by UV flatbed printers is outstanding. The technology enables high-resolution images with vivid colors and sharp details, ensuring the final product meets the highest standards. This is especially important for businesses that rely on visual appeal to attract customers, such as the fashion, interior design and advertising industries.

Additionally, UV flatbed printers are known for their efficiency. The curing process is fast, meaning the job can be completed faster than traditional printing methods. This speed not only increases productivity but also enables businesses to meet tight deadlines without compromising quality.

All in all, UV Flatbed Printers are a game changer for the printing industry. Its versatility, high-quality output and efficiency make it a valuable asset for businesses looking to innovate and expand their product range. As technology continues to evolve, the potential applications for UV lithography are endless, paving the way for exciting developments in the future.

Post time: Nov-07-2024